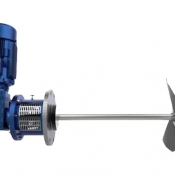

Mixing Agitator

A mixing agitator is a mechanical device used to mixed liquids, slurries, or powders in various industrial processes. It consists of key components such as a gearbox, motor, shaft, and blade that work together to generate controlled fluid movement within a tank.

APPLICATIONS:

- Chemical Preparation Unit

- Sludge Preparation Unit.

- Food Production

- Pharmaceuticals

- Textile Unit.

- Water & Wastewater Treatment

- Oil & Gas Industry

- Paint & Coatings Industry

- Biotechnology & Fermentation

- Mining & Minerals Processing

- Paper & Pulp Industry

- Power Plants

FEATURES:

- Efficient Mixing: Ensures uniform blending of fluids and solids.

- High-Performance Impellers: Designed for optimal flow patterns and turbulence control.

- Customizable Speed & Power: Available in different motor capacities to suit process needs.

- Durable Construction: Built with stainless steel, carbon steel, or coated materials for corrosion resistance.

- Multiple Mounting Options: Can be mounted on tanks, reactors, or open vessels.

- Energy-Efficient Design: Reduces power consumption while maintaining high performance.

MAIN COMPONENTS:

- Motor: Provides the necessary rotational power to drive the agitator.

- Gearbox: Reduces motor speed and increases torque for efficient mixing.

- Shaft: Connects the motor and gearbox to the impeller, transmitting rotational motion.

- Blade : The mixing element that agitates the fluid, creating flow patterns for uniform blending.

Published on: Wednesday, 7 May 2025, 05:18 pm ▪ Last update: Wednesday, 14 May 2025, 01:21 pm ▪ Total View of this Page: 403

.png)